Daily Current Affairs : 19-August-2023

In a technological leap, India recently witnessed the unveiling of its first-ever 3D-printed post office located in Bengaluru’s Cambridge Layout. This remarkable feat was accomplished through the collaborative efforts of multinational giant Larsen & Toubro Limited and technological support from the esteemed institution, IIT Madras. The emergence of 3D printing technology and its successful application in constructing a post office opens new avenues for innovation and efficiency in various industries. This essay explores the significance of 3D printing, its operation, and notable examples of its recent applications.

The Relevance of 3D Printing

Historical Evolution

The concept of 3D printing, also referred to as additive manufacturing, was first conceived in the 1980s. However, it only gained widespread recognition around the 2010s. In its early days, 3D printing faced challenges such as high costs, slow production speeds, and a propensity for errors. These limitations hindered its integration into various sectors.

Recent Advancements

In recent years, substantial progress has been made in overcoming these shortcomings. As a result, 3D printing has become more prevalent than ever before. Its applications extend to diverse industries, including automotive and aerospace, where it is used to craft parts for cars and rockets, respectively.

Understanding 3D Printing

The Process

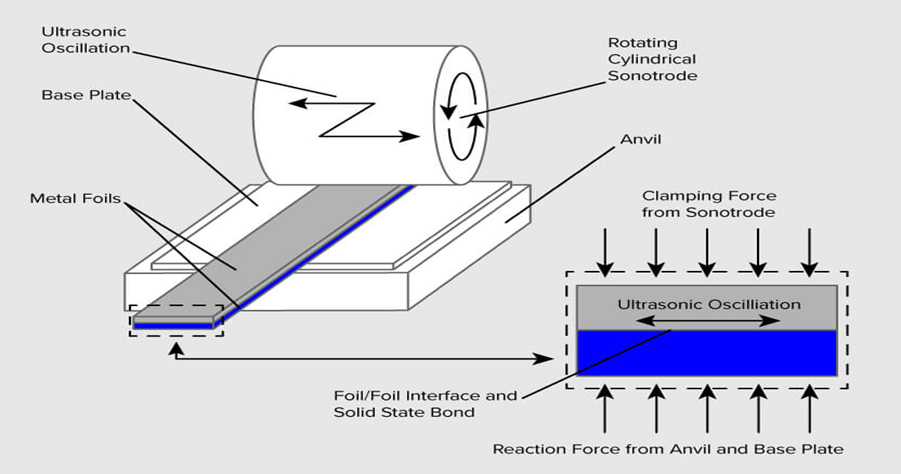

3D printing is an innovative process that relies on computer-generated designs to fabricate three-dimensional objects layer by layer. This additive manufacturing process involves the gradual buildup of materials, such as plastic, composites, or bio-materials, to create objects of varying shapes, sizes, rigidity, and color.

Operational Procedure

To engage in 3D printing, one requires a personal computer connected to a 3D printer. The user designs a 3D model of the desired object using computer-aided design (CAD) software and initiates the printing process. The 3D printer then takes over, constructing the object layer by layer. This method essentially involves stacking hundreds or thousands of 2D prints on top of each other until the envisioned three-dimensional object is formed.

Notable Examples of 3D Printing

In Aerospace

Aerospace manufacturing company Relativity Space made headlines by launching a test rocket entirely comprised of 3D-printed parts. This monumental rocket stood at an impressive height of 100 feet and spanned 7.5 feet in width. Although this endeavor faced an unfortunate failure during its maiden flight, it underscored the potential of 3D printing in revolutionizing the aerospace industry.

During the Pandemic

In 2020, amid the peak of the Covid-19 pandemic, the healthcare industry harnessed the power of 3D printing to address critical shortages of medical equipment. 3D printers were utilized to produce essential items such as swabs, face shields, masks, and even components required for ventilator repairs. This rapid response demonstrated the versatility and adaptability of 3D printing technology in times of crisis.

Important Points:

- India’s first 3D-printed post office was recently constructed in Bengaluru’s Cambridge Layout.

- The project was a collaboration between Larsen & Toubro Limited and IIT Madras.

- 3D printing, or additive manufacturing, gained prominence around the 2010s.

- Early 3D printing technology had issues like high costs, slow production, and errors.

- Recent advancements have made 3D printing more prevalent and practical.

- It’s now used in industries like automotive and aerospace for part production.

- 3D printing involves computer-generated designs and additive layering of materials.

- The process is initiated by designing a 3D model on computer-aided design (CAD) software.

- 3D printers build objects layer by layer, adding 2D prints on top of each other.

- Notable examples include Relativity Space’s 3D-printed rocket and the healthcare industry’s use during the pandemic.

- Relativity Space’s rocket, though it experienced a failure, showcased 3D printing’s potential in aerospace.

- During the pandemic, 3D printers produced essential medical equipment and ventilator components.

- 3D printing holds promise for cost-effective, customizable solutions across various industries.

Why In News

In a groundbreaking achievement, India’s inaugural 3D-printed post office was unveiled in the charming Cambridge Layout of Bengaluru. This innovative postal facility marks a significant stride towards embracing advanced technology in everyday infrastructure, showcasing India’s commitment to modernization and efficiency.

MCQs about India’s First 3D-Printed Post Office

-

India’s first 3D-printed post office was constructed in which location?

A. Bengaluru’s Whitefield

B. Bengaluru’s Cambridge Layout

C. New Delhi’s Connaught Place

D. Mumbai’s Bandra

-

What is the main advantage of 3D printing technology today, compared to its early days?

A. It is less environmentally friendly

B. It is faster and less expensive

C. It uses subtractive manufacturing methods

D. It relies on molding techniques

-

What industry sectors use 3D printing for part production?

A. Construction and agriculture

B. Healthcare and fashion

C. Automotive and aerospace

D. Food and entertainment

-

How did 3D printing contribute during the peak of the Covid-19 pandemic in 2020?

A. It was used to produce 3D-printed rockets

B. It contributed to the construction of India’s first 3D-printed post office

C. 3D printers created essential medical equipment and ventilator components

D. It was used to design custom clothing for healthcare workers

Boost up your confidence by appearing our Weekly Current Affairs Multiple Choice Questions

![]()