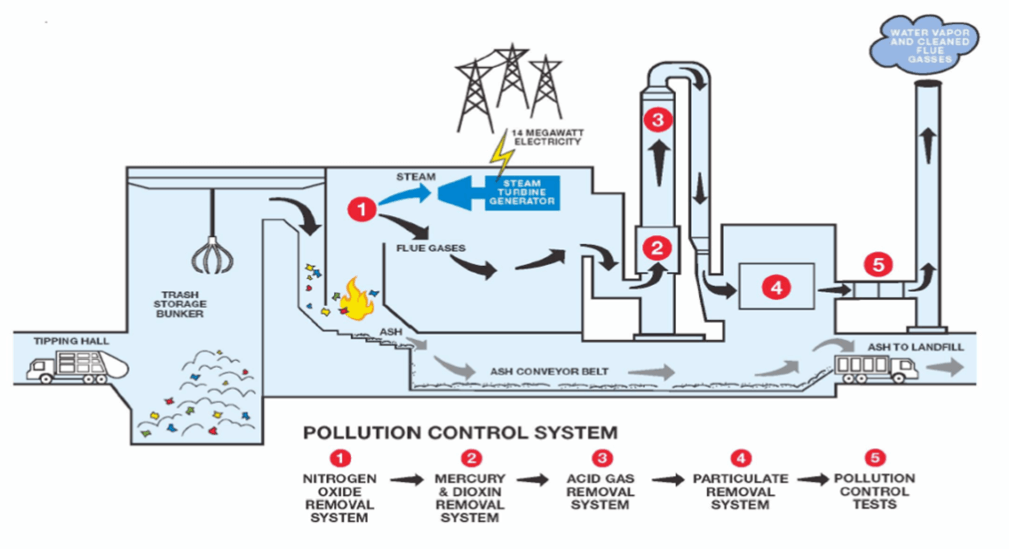

A waste-to-energy plant is a facility that manages waste by combusting it to produce electricity. Most of these plants burn municipal solid waste, but some also burn industrial or hazardous waste. Waste-to-energy projects utilize non-recyclable dry waste to generate electricity. The process increases power generation capacity and eases the burden of solid waste management.

Why India Needs Waste-to-Energy Plants

In India, solid waste consists of 55-60% biodegradable organic waste, 25-30% non-biodegradable dry waste, and 15% silt, stones, and drain waste. Only 2-3% of the non-biodegradable dry waste, including hard plastics, metals, and e-waste, is recyclable. The remainder consists of low-grade plastic, rags, and cloth that cannot be recycled.

This portion of non-recyclable dry waste poses a significant challenge to the current solid waste management system. Waste-to-energy plants use this fraction of non-recyclable dry waste to generate power. The waste is combusted to generate heat, which is then converted into electricity.

Challenges of Waste-to-Energy Plants

- Waste-to-energy plants in India face significant challenges, including low calorific value of solid waste due to improper segregation.

- The mixed waste in India has a calorific value of around 1,500 kcal/kg, which is not suitable for power generation, whereas coal’s calorific value is around 8,000 kcal/kg.

- Biodegradable waste has high moisture content and cannot be used for power generation, while the calorific value of segregated and dried non-recyclable dry waste is higher, at 2,800-3,000 kcal/kg, sufficient to generate power.

- To ensure waste-to-energy plants can generate power, segregation should be streamlined to ensure the waste coming to the facility has the required calorific value.

- The high cost of energy production is another challenge faced by waste-to-energy plants in India, with the cost of generating power from waste around ₹7-8/unit compared to the ₹3-4/unit at which electricity boards buy power from other sources.

- Improper assessments, high expectations, improper characterization studies, and other on-ground conditions have also contributed to many waste-to-energy projects failing.

Solution

To overcome the challenges of waste-to-energy plants, strict segregation practices should be followed, and biodegradable waste should be processed separately. Waste-to-energy projects also depend on parameters such as municipal collection efficiency, waste segregation, moisture content, and the operational efficiency of existing biodegradable waste processing plants.

The municipality or the department responsible for SWM should be practical about the high cost of power generation and include the State electricity department in a tripartite agreement between the municipality, the plant operator, and the power distribution agency. It is also crucial to conduct field studies and learn from the experience of other projects.

Why In News

The Kerala government’s announcement of its first waste-to-energy project in Kozhikode is a significant step towards addressing the state’s solid waste management issues and increasing its power generation capacity.This waste-to-energy project in Kozhikode is expected to set an example for other states in India to follow and encourage the adoption of more sustainable and environmentally friendly waste management practices.

MCQs about Waste-to-Energy Plants

-

ChatGPT can create questions based on the waste-to-energy project in Kozhikode:

A. True

B. False

-

What is the calorific value of mixed Indian waste?

A. 8,000 kcal/kg

B. 3,000 kcal/kg

C. 1,500 kcal/kg

D. 2,000 kcal/kg

-

What is the cost of generating power from waste?

A. ₹7-8/unit

B. ₹3-4/unit

C. ₹1-2/unit

D. ₹5-6/unit

-

What are some of the reasons for the failure of waste-to-energy projects?

A. Improper assessments and high expectations

B. Proper characterisation studies and on-ground conditions

C. High investments and low demand

D. Adequate funding and government support

Boost up your confidence by appearing our Weekly Current Affairs Multiple Choice Questions

![]()